The Mac

@TheMac

23 April, 10:57

At what point do you say to yourself these f were willing to vaccinate children with mind control nanoparticles regardless of the oxidative stress side effects?

Notice: Undefined index: tg1tga_access in /home/admin/www/anonup.com/themes/default/apps/timeline/post.phtml on line 396

••• Bender •••

@4dBender

23 April, 11:02

In response The Mac to his Publication

I would probably say that to myself when the probability of it being true reached near 100%. I haven't looked at enough evidence of the nanoparticles to know either way. I haven't seen "nanoparticle" in the ingredients, so I need to learn more about it, but the mRNA is also concerning.

Notice: Undefined index: tg1tga_access in /home/admin/www/anonup.com/themes/default/apps/timeline/post.phtml on line 396

The Mac

@TheMac

23 April, 11:04

In response ••• Bender ••• to his Publication

Notice: Undefined index: tg1tga_access in /home/admin/www/anonup.com/themes/default/apps/timeline/post.phtml on line 396

••• Bender •••

@4dBender

23 April, 11:22

In response The Mac to his Publication

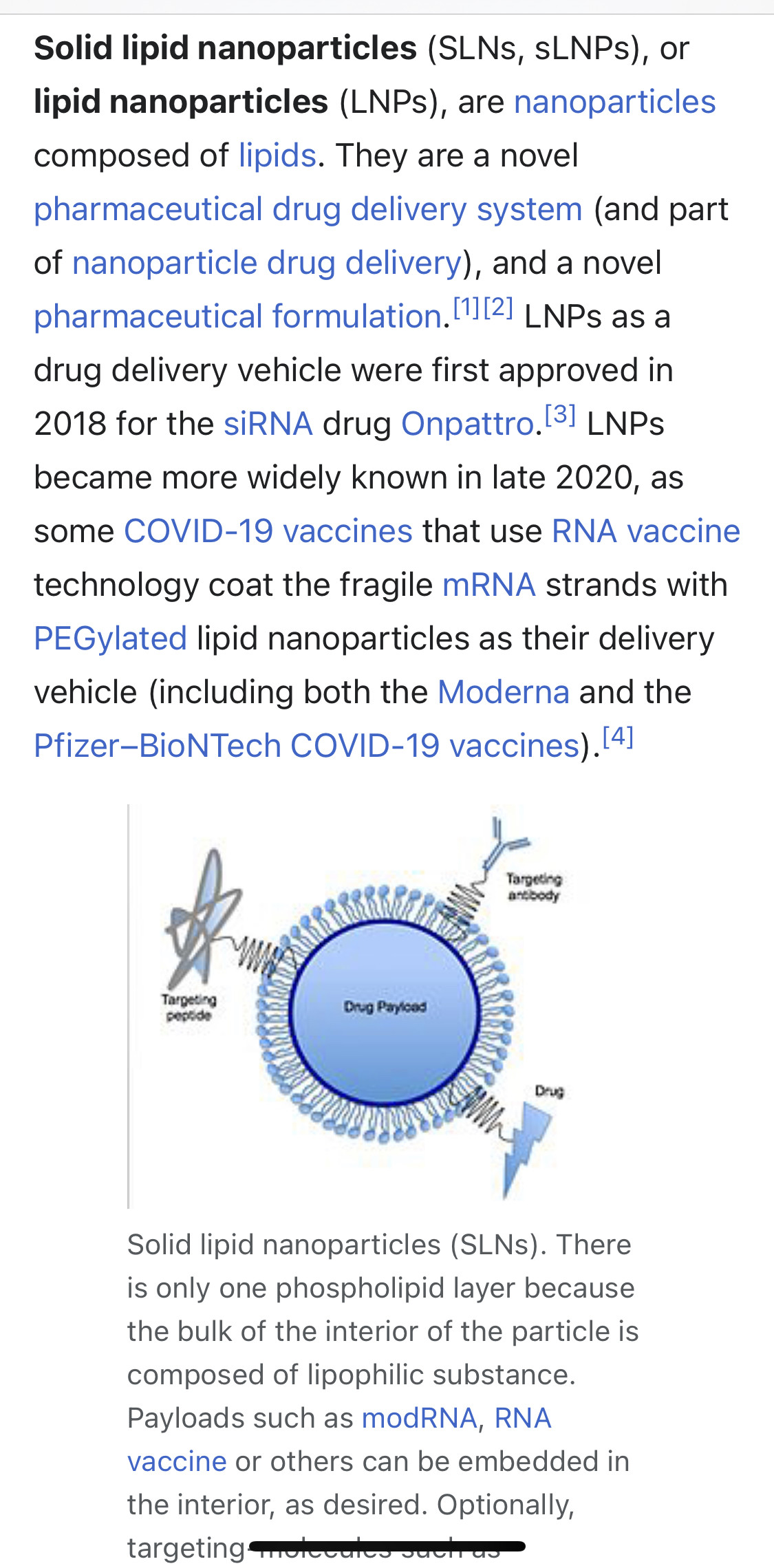

Here is Pfizer and BioNTech Lipid Nanoparticle, ALC-0315.

Off topic, but interesting note that this line says the more acidic certain cells in the body are, the more mRNA payload is delivered.

"the more acidic environment within the endosome fully protonates the ALC-0315 as a result the nanoparticle releases its payload of mRNA"

https://en.wikipedia.org/w...

Off topic, but interesting note that this line says the more acidic certain cells in the body are, the more mRNA payload is delivered.

"the more acidic environment within the endosome fully protonates the ALC-0315 as a result the nanoparticle releases its payload of mRNA"

https://en.wikipedia.org/w...

Notice: Undefined index: tg1tga_access in /home/admin/www/anonup.com/themes/default/apps/timeline/post.phtml on line 396

The Mac

@TheMac

23 April, 11:40

In response ••• Bender ••• to his Publication

1.2.1.3 External Fields (Ultrasound, Laser, Electromagnetic) The principal benefit of using external fields, such as ultrasound or laser, to control nucleation lies in avoiding the problems typically encountered with conventional seeding; inconsistent seed attributes and seed history, incomplete seed wetting and dispersion resulting in polycrystalline particle formation, seed dissolution due to delayed seed addition, etc. Well-controlled nucleation offers the possibility of exquisite control of product particle size.

Notice: Undefined index: tg1tga_access in /home/admin/www/anonup.com/themes/default/apps/timeline/post.phtml on line 396

The Mac

@TheMac

23 April, 11:41

In response The Mac to his Publication

These aspects are particularly important in continuous crystallization where seeding is an essential element in the start-up process required to minimize the peak supersaturation attained and so to delay the onset of encrustation. The benefit of externally induced nucleation in starting up a continuous crystallization is that it can be initiated at supersaturation levels lower than the metastable zone limit for spontaneous nucleation and potentially at levels lower than would be considered robust for conventional seed addition.

Notice: Undefined index: tg1tga_access in /home/admin/www/anonup.com/themes/default/apps/timeline/post.phtml on line 396

The Mac

@TheMac

23 April, 11:41

In response The Mac to his Publication

In a classical continuous crystallization, following successful initiation via seed addition, the next major operational challenge is to manage the secondary nucleation rate such that the available surface area for crystal growth is commensurate with achieving almost complete desupersaturation within the target residence time whilst also producing crystals with the required size distribution. Typical strategies for commodity materials manufacture revolve around making large particles which are easy to isolate by filtration and washing. This is usually achieved by actively suppressing nucleation and operating at modest supersaturations with extended residence times.

Notice: Undefined index: tg1tga_access in /home/admin/www/anonup.com/themes/default/apps/timeline/post.phtml on line 396

The Mac

@TheMac

23 April, 11:44

In response The Mac to his Publication

1.2.1.3.1 Ultrasound-induced Nucleation Sonocrystallization is the application of ultrasound to influence crystallization processes. The most common approach may be more accurately termed “sononucleation” where ultrasound is used to trigger controlled primary nucleation. Insonation can also make a distinctive contribution by generating new particles through breakage of existing crystals (see next section on secondary nucleation) allowing operation at low supersaturation levels whilst maintaining a large population of crystals which are appropriately small for direct formulation.

Notice: Undefined index: tg1tga_access in /home/admin/www/anonup.com/themes/default/apps/timeline/post.phtml on line 396

The Mac

@TheMac

23 April, 11:44

In response The Mac to his Publication

This can allow breaking of the constraints of conventional continuous crystallization process design.

The mechanism by which ultrasound triggers nucleation is not fully understood, however, it is widely accepted that cavitation plays a central role. A sound wave propagates through a solution as alternating periods of compression and rarefaction. Acoustic intensity, the amplitude of the wave, can be expressed in microns of displacement of the source of the sound. When the amplitude of the sound wave is sufficiently large cavitation occurs and bubbles form from the release of dissolved gas and evaporated solvent vapor.

The mechanism by which ultrasound triggers nucleation is not fully understood, however, it is widely accepted that cavitation plays a central role. A sound wave propagates through a solution as alternating periods of compression and rarefaction. Acoustic intensity, the amplitude of the wave, can be expressed in microns of displacement of the source of the sound. When the amplitude of the sound wave is sufficiently large cavitation occurs and bubbles form from the release of dissolved gas and evaporated solvent vapor.

Notice: Undefined index: tg1tga_access in /home/admin/www/anonup.com/themes/default/apps/timeline/post.phtml on line 396

These bubbles shrink during the compression phase and then they expand again during the subsequent rarefaction phase as the sound wave propagates (this repeating oscillation is known as stable cavitation). If the amplitude of the sound wave is large enough bubbles of solvent vapor form during the rarefaction. These bubbles can coalesce and transient cavitation may occur. Under appropriate conditions bubbles increase in size cycle by cycle until they reach a critical size, perhaps 100–200 µm, when they collapse catastrophically.

11:45 PM - Apr 23, 2022

In response The Mac to his Publication

Only people mentioned by TheMac in this post can reply